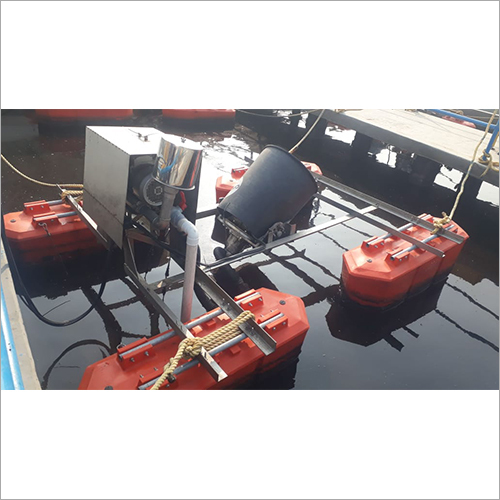

Dissolved Air Flotation Technology

Product Details:

- Material Mild Steel

- Automatic Grade Full Automatic

- Drive Type Electric

- Water Source Ground Water

- Voltage 220-240 Volt (v)

- Click to View more

Dissolved Air Flotation Technology Price And Quantity

- 1 Piece

Dissolved Air Flotation Technology Product Specifications

- Ground Water

- 220-240 Volt (v)

- Electric

- Mild Steel

- Full Automatic

Dissolved Air Flotation Technology Trade Information

- Cash in Advance (CID)

- 1000 Piece Per Month

- 7 Days

- All India

Product Description

The following steps are a part of the DAF process:

- Coagulation and flocculation: In order to destabilise and aggregate fine particles and colloidal matter before the DAF process, chemicals known as coagulants are added to the water. To help create larger flocs, flocculants may also be applied.

- Water Saturation with Air: After the water is pressurised and added to a tank or basin, air is dissolved there as a result of the pressure. Air can dissolve into the water as a result of the saturation process, creating small bubbles.

- The pressurised water with dissolved air is released into a flotation tank or basin, where bubbles form and attach. The dissolved air escapes from solution as the water pressure is decreased, creating small bubbles. These bubbles form buoyant flocs by adhering to the particles and impurities in the water.

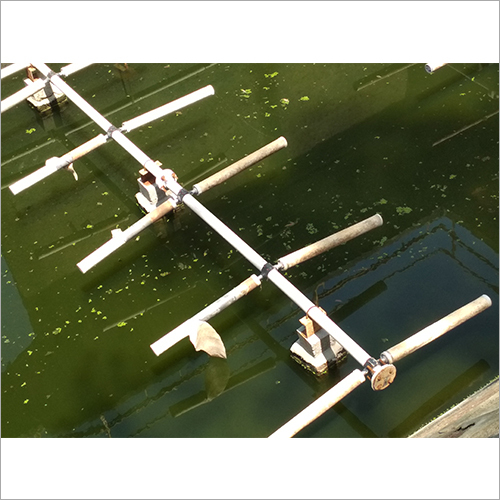

- Flotation and Separation: The associated air bubbles produce flocs that ascend to the top of the flotation tank and form a layer that floats, known as the float. Using mechanical scrapers or skimmers, the float which contains the suspended materials and contaminants is removed from the water's surface.

- Clarification: The bottom of the flotation tank releases the cleared water, which is free of pollutants and suspended solids. Depending on the unique needs, it may need to be further treated or discharged.

The following benefits of DAF technology for water treatment:

- Effective Contaminant Removal: DAF is efficient at removing oils, greases, and other particulates from water, leaving behind a cleared effluent.

- Flexibility: DAF systems are capable of handling a wide range of feed water parameters, including changes in temperature, pH, and solids concentration.

- Compact Design: Compared to other traditional water treatment methods, DAF systems are typically small and take up less room.

- Reduced Chemical Usage: DAF frequently uses lesser chemical dosages than other treatment strategies, saving money.

- Easy Operation and Maintenance: DAF systems require little operator intervention and are very simple to run and maintain.

Dissolved air flotation technique is frequently utilised in a variety of industries, including pulp and paper mills, chemical production, wastewater treatment facilities, oil refineries, food and beverage processing, and food and beverage processing.

It's important to note that DAF systems might have some restrictions, such as the inability to remove certain kinds of chemicals or dissolved pollutants. The qualities of the water being treated can also affect how well the process works. To achieve desired performance and efficiency, proper system design, optimisation, and routine maintenance are crucial.

FAQ

1. What is Dissolved Air Flotation (DAF) Technology, please explain?

Ans - The water treatment method known as dissolved air flotation (DAF) clears wastewaters (or other waterways) by removing suspended particles like oil or sediments. By dissolving air under pressure in water or wastewater and releasing it at atmospheric pressure in a flotation tank basin, the removal is accomplished. The released air creates tiny bubbles that stick to the suspended material, enabling it to float to the water's surface where it can be skimmed off using a device.

2. What advantages does DAF Technology offer?

Ans - DAF technology has a number of advantages, such as increased water clarity, better suspended particles settling, improved water quality, lower operational costs, less chemical use, and increased safety.

3. How is DAF Technology used?

Ans - DAF technology is used to treat wastewater in a number of industries, including oil and gas production, food and beverage processing, municipal wastewater, and industrial wastewater.

4. What kinds of impurities are capable of being eliminated using DAF Technology?

Ans - A number of pollutants, including as oil, suspended particles, colloidal debris, and certain metals, can be eliminated using DAF technology.

5. What kinds of DAF Technology systems are offered?

Ans - There are numerous DAF systems available, including inclined, circular, and rectangular plate systems. The application and the expected outcomes will determine the sort of system to be used.