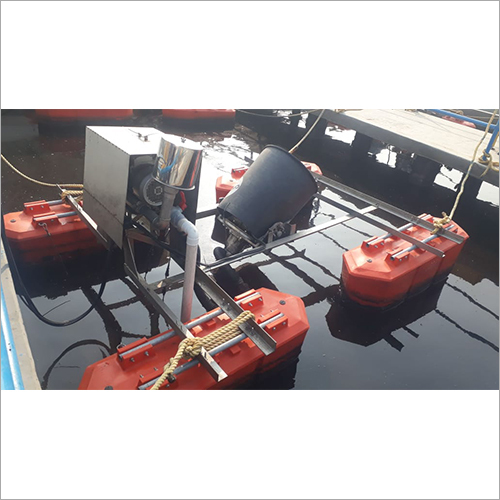

Drum Type Fine Screen

Product Details:

- Material Mild Steel

- Drive Type Electric

- Voltage 220-240 Volt (v)

- Water Source Ground Water

- Automatic Grade Full Automatic

- Click to View more

Drum Type Fine Screen Price And Quantity

- 1 Piece

Drum Type Fine Screen Product Specifications

- Full Automatic

- Ground Water

- 220-240 Volt (v)

- Electric

- Mild Steel

Drum Type Fine Screen Trade Information

- Cash in Advance (CID)

- 1000 Piece Per Month

- 7 Days

- All India

Product Description

The drum is regularly cleaned while it is running to avoid clogging and maintain effective screening. The trapped solids are normally removed from the surface of the drum using various devices, such as spray nozzles, brushes, or scraper blades. The removed solids are gathered and released for additional processing or disposal.

Fine solids, debris, fibres, and other particles can be effectively removed from liquids, such as wastewater, industrial process water, and municipal water, using drum type fine screens. They are frequently employed in wastewater treatment facilities as the first stage of solids removal prior to biological treatment or disinfection.

Drum type fine screens have the benefits of being compact, highly effective at removing particles, and able to handle enormous amounts of liquid. They can be automated for continuous operation and are also comparatively low-maintenance devices.

It's crucial to remember, nevertheless, that not all applications may be appropriate for drum type fine screens. The size of the screen and the number of perforations must be carefully chosen depending on the particular requirements of the operation because they can be restricted in their ability to handle particular types of solids or particles.

In conclusion, a mechanical screening tool used to separate fine solids and particles from liquids is known as a drum type fine screen. It uses a revolving cylindrical drum with holes or mesh apertures to separate the liquid from the particles, which improves the quality of the water and helps many industrial processes - particularly wastewater treatment run more smoothly.

FAQ

1. What exactly is a fine drum screen?

Ans - A mechanical screening tool used to separate particles in a liquid or solid-liquid mixture is called a drum type fine screen. It consists of a cylindrical drum with a perforated screen or other filtering material that revolves around its axis. The material can pass through the filter thanks to the rotating drum, and the scraper removes the material that was retained from the surface.

2. What advantages do drum-style fine screens offer?

Ans - The drum type fine screen has a number of advantages, including improved efficiency, capacity, and safety. It is simple to use and requires little upkeep. The screen is appropriate for a number of applications because it can filter out particles of a wider range of sizes than other types of filters.

3. What materials can be screened using a fine drum screen?

Ans - Plastics, powders, oils, and food ingredients can all be screened using a fine screen of the drum type. Screening recyclable materials like paper, glass, and metals is another usage for it.

4. How do I care for a fine drum screen?

Ans - The drum type fine screen needs to be frequently inspected and cleaned in order to operate at peak efficiency. Examine the equipment for any worn or broken parts and replace them as necessary. Regularly clean the screen to get rid of any material accumulation.

5. What safety measures need to be followed when utilising a drum-style fine screen?

Ans - It's crucial to take safety precautions when utilising a drum-style fine screen to protect both the operator and the surrounding area. Wear safety gear, such as gloves and a face mask, to prevent coming into touch with the substance accidentally. Before performing any maintenance or cleaning, turn off the power supply.