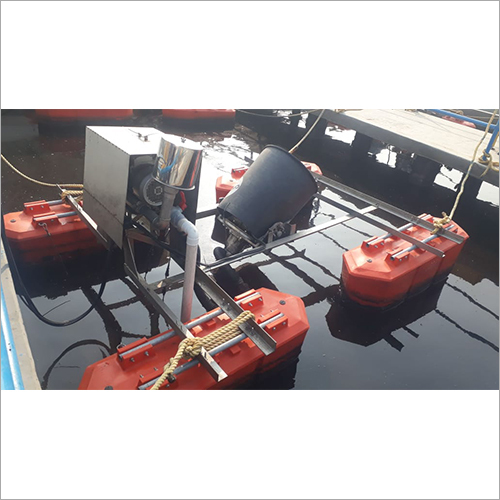

Electrocoagulation with DAF

Product Details:

- Recycle Rate m3/hr

- Automatic Grade Full Automatic

- Voltage 415-420 Volt (v)

- Material HDPE

- Drive Type Electric

- Power Source DC

- Water Source Other

- Click to View more

Electrocoagulation with DAF Price And Quantity

- 1 Cubic Meter

- 1.00 - 1.00 INR/Unit

Electrocoagulation with DAF Product Specifications

- Other

- m3/hr

- 415-420 Volt (v)

- Full Automatic

- HDPE

- DC

- Electric

Electrocoagulation with DAF Trade Information

- 100 Cubic Meter Per Month

- 8 Days

- Middle East

- All India

Product Description

An electrochemical reaction is used to remove impurities from water, and then flotation is used to separate solids from liquids in the electrocoagulation and dissolved air flotation (DAF) water treatment process. In applications for industrial water treatment and wastewater treatment, this combination is frequently used.

The following steps are often included in the process:

1. The water that needs to be treated is run through an electrocoagulation cell. In this cell, metal ions, usually aluminium or iron, are produced through an electrochemical process using sacrificial electrodes. The pollutants in the water become unstable and coagulate, which causes them to combine and create bigger particles.

2. Flocculation: To improve the aggregation and settling of the coagulated particles, a flocculant or coagulant aid may be applied after the electrocoagulation stage. This process aids in the production of larger, more easily separated flocs.

3. The coagulated and flocculated water is then added to a machine that uses dissolved air flotation (DAF). Air is dissolved under pressure in the DAF unit before being discharged in the flotation tank. The flocs are attached to the tiny bubbles created by the expelled air, which lifts them to the tank's surface.

4. Surface skimming: As the flocs rise to the surface, a layer of sludge forms that is frequently referred to as the "float." After being mechanically skimmed off the tank's surface, the float is then collected for further processing or disposal.

5. Clarification and Effluent Discharge: The treated effluent is discharged as the cleared water, which has been removed from the bottom of the flotation tank and is largely free of pollutants and suspended materials.

When electrocoagulation and DAF are used, water treatment benefits include:

1. Enhanced Contaminant Removal: The removal of a variety of pollutants, including suspended particles, metals, oils, grease, and some organic compounds, is accomplished by electrocoagulation. These coagulated pollutants are further separated from and removed using the DAF process.

2. Effective Method of Separating Coated Particles from Water: The DAF unit offers an effective method of separating the coagulated particles from the water. Even smaller particles can be removed thanks to flotation, which also results in clearer effluent.

3. Flexibility: Different water types and treatment scenarios can use electrocoagulation with DAF. Depending on the particular qualities of the water and the contaminants present, the method might be modified.

4. Reduced Chemical Use: Because the metal ions produced during the electrochemical process serve as coagulants, electrocoagulation can reduce the need for conventional coagulants and flocculants. By doing this, the treatment process's chemical footprint can be reduced and costs could be cut.

It's crucial to remember that the effectiveness of electrocoagulation with DAF can change based on elements including the water's composition, the type and quantity of contaminants, and the treatment system's setup and operation. For the process to run smoothly and produce the best outcomes, proper monitoring, maintenance, and optimisation are required.

An electrochemical reaction is used to coagulate and aggregate pollutants in the electrocoagulation combined with dissolved air flotation (DAF) method for treating water. Flotation is then used to separate solids from liquids. A cleared effluent is produced as a result of this combination's efficient removal of suspended particles, metals, oils, and other pollutants.

FAQ

1. What is DAF-electroconcoagulation?

Ans - In order to coagulate and flocculate suspended particles, oils, and other pollutants from wastewater, electrocoagulation with dissolved air flotation (DAF) is a water treatment method. The wastewater is processed using an electrocoagulation reactor that has an electrical field inside of it. By bonding the suspended particles together in this field, bigger particles are created that can be extracted via flotation.

2. How does DAF electrocoagulation operate?

Ans - The wastewater is passed through an electrocoagulation reactor with an electrical field to achieve electrocoagulation with DAF. By bonding the suspended particles together in this field, bigger particles are created that can be extracted via flotation. Air is also added to the wastewater throughout the process, which aids in the formation of larger flocs that are easier to remove.

3. What are the advantages of DAF and electrocoagulation?

Ans - An extremely efficient method for removing oils, suspended particles, and other pollutants from wastewater is electrocoagulation with DAF. Without the use of any chemical additions, it is a procedure that is both economical and energy-efficient. It is also a rather rapid procedure that can be used to treat big amounts of wastewater quickly.

4. Which wastewater types are amenable to electrocoagulation with DAF treatment?

Ans - An extensive range of wastewater, including industrial, municipal, and agricultural wastewater, can be treated using electrocoagulation and DAF. The method is particularly good at getting rid of impurities including oils, suspended particles, and other pollutants from wastewater.

5. Does electrocoagulation with DAF have any drawbacks?

Ans - The main disadvantage of electrocoagulation with DAF is that it may become foul if the wastewater has a high organic matter content. In order to ensure effective therapy, it's also crucial to make sure the electrical current is calibrated properly.