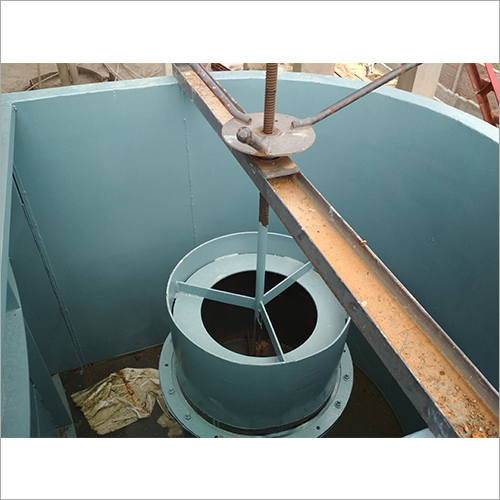

Sludge Dewatering Machine

Product Details:

- Power Source Electric

- Material Mild Steel

- Automatic Grade Full Automatic

- Voltage 220-240 Volt (v)

- Click to View more

Sludge Dewatering Machine Price And Quantity

- 500000 INR/Unit

- 1 Piece

Sludge Dewatering Machine Product Specifications

- 220-240 Volt (v)

- Electric

- Mild Steel

- Full Automatic

Sludge Dewatering Machine Trade Information

- 100 Piece Per Month

- 15 Days

- All India

Product Description

A sludge dewatering machine, often referred to as a sludge dehydrator or a sludge drying machine, is a tool used to remove moisture from sludge or wastewater particles, producing less sludge but with a higher concentration of solids. Sludge dewatering is a crucial step in the treatment of sewage because it lowers the expense of sludge disposal and transportation.

Sludge dewatering devices come in a variety of varieties and employ various methodologies and technology.

Here are a few often employed types:

- The Belt Filter Press is a sort of dewatering device that works by circulating a number of porous belts through a number of rollers. As the belts move, the water drains through the porous belts, leaving behind dewatered sludge. The sludge is fed onto the belts.

- A revolving screw is contained within a cylindrical screen in a screw press dewatering device. After being fed into the machine, the sludge is compressed and squeezed against the screen by the rotating screw, which forces the water to escape through the screen perforations.

- Centrifuge: To separate solids from liquids, centrifuges use centrifugal force. The sludge is put into a revolving drum, where the centrifugal force forces the liquid to be ejected through nozzles and the solids to settle against the drum wall. The machine then discharges the dewatered sludge.

- Filter Press: To dewater the sludge, a filter press employs a number of filter plates and frames. Pumping the sludge into the press causes pressure to push the water through the filter plates, removing it and leaving behind dewatered sludge cakes.

- Drying Beds: A quick and inexpensive way to dewater sludge are drying beds. On shallow beds, the sludge is dispersed and left to air dry naturally in the wind and sun. Dewatered sludge is left behind after the water evaporates.

These are merely a few instances of sludge dewatering equipment used frequently in wastewater treatment facilities. The properties of the sludge, intended ultimate moisture content, throughput requirements, available space, and financial restraints all play a role in the dewatering machine selection process.

Sludge dewatering devices can greatly lower the moisture content of sludge, although they could not completely dry it off. Depending on the particular needs and laws, further techniques like thermal drying or cremation may be used to further reduce the moisture content and volume of the dewatered sludge.

The dewatering machine must be properly maintained and monitored to guarantee both its long life and excellent performance. To prevent operating concerns and guarantee effective sludge dewatering, routine cleaning, inspections, and part replacements are required.

FAQ

1. What does a dewatering sludge machine do?

Ans - A sludge dewatering machine is a tool used to lower the moisture content of liquid waste produced by industrial processes known as sludge. By exerting pressure on the sludge, the machine forces the water out, leaving behind a more solid substance with a higher dry matter content.

2. How does a dewatering device for sludge operate?

Ans - By exerting pressure on the sludge, a sludge dewatering machine forces the water out, leaving behind a more solid substance with a greater dry matter content. This is normally done by the machine using a screw press, belt press, centrifuge, or filter press.

3. What advantages can sludge dewatering machines offer?

Ans - The amount of sludge produced can be decreased by using a sludge dewatering machine, which can result in lower disposal costs. Additionally, the sludge's weight is decreased, making it simpler to handle and transport. The procedure also helps to increase the material's safety and lessen odours.

4. Which sludge kinds can be processed by a sludge dewatering device?

Ans - Municipal, industrial, food processing, and agricultural sludge are just a few of the various forms of sludge that a sludge dewatering machine can handle.

5. What upkeep is necessary for a sludge dewatering device?

Ans - Regular maintenance is necessary to keep a sludge dewatering machine operating effectively. This include lubricating the screws and belts in addition to cleaning the filter plates and replacing the filter media. Additionally, it's critical to routinely inspect the machine to make sure it's operating effectively.