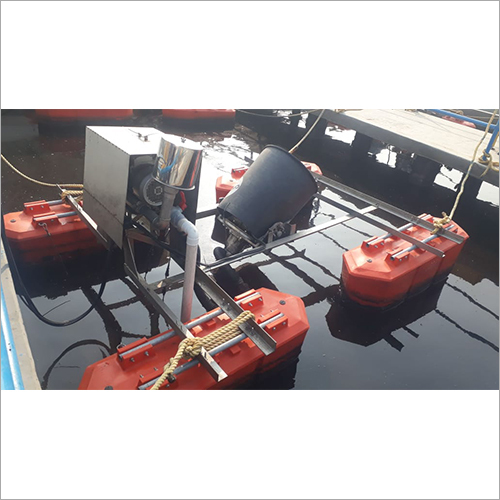

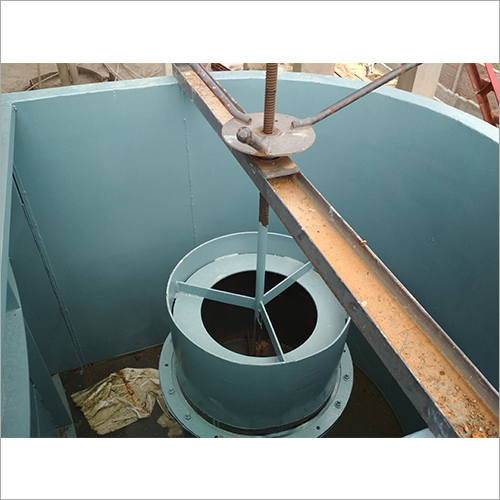

Half Drum Type Screen

Product Details:

- Automatic Grade Full Automatic

- Material Mild Steel

- Water Source Ground Water

- Drive Type Electric

- Voltage 220-420 Volt (v)

- Click to View more

Half Drum Type Screen Price And Quantity

- 1 Piece

Half Drum Type Screen Product Specifications

- Full Automatic

- 220-420 Volt (v)

- Ground Water

- Mild Steel

- Electric

Half Drum Type Screen Trade Information

- Cash in Advance (CID)

- 1000 Piece Per Month

- 7 Days

- All India

Product Description

Several industries, including wastewater treatment, mining, and food processing, use half drum type screens. They are a flexible and successful method for removing particulates from liquids.

The following are some advantages of adopting a half-drum-style screen:

- Effective: Half drum-style screens are excellent at separating solids from liquids. Depending on the mesh size, they can eliminate up to 99% of the solids.

- Half drum type screens are versatile and can be used in many different industries. They are a well-liked option for mining, food processing, and wastewater treatment.

- Half drum type screens are constructed from sturdy materials like steel or stainless steel. They are therefore resistant to wear and corrosion.

- Low upkeep: Screens in the shape of half drums require relatively little maintenance. They are simple to use and clean.

Half drum-style screens have a variety of advantages overall. They are effective, adaptable, long-lasting, and low-maintenance. A half drum type screen is a fantastic option if you're looking for a means to separate solids from liquids.

The following are some disadvantages of using a half drum-style screen:

- Costly: Half drum style screens may be costly, especially if they are constructed from premium materials.

- Enormous: Screens that resemble half-drums can be hefty and enormous. They could be challenging to install and run as a result.

- Noise: Half-drum displays have a tendency to make noise while in use. In certain circumstances, this might be an issue.

Half drum-style screens have a variety of advantages overall. They can, however, also be pricy, big, and noisy. Consider the advantages and disadvantages of utilising a half drum type screen before deciding if it is the best option for your needs.

FAQ

1. What is a half drum-style screen, exactly?

Ans - A form of screen used to separate materials in a number of industries is the half drum type screen. A mesh screen is firmly stretched across the centre of a circular metal frame. The material is typically separated from the mesh by the frame being mounted on a revolving drum that rotates rapidly.

2. A half drum type screen has what purpose?

Ans - A half drum type screen is used to separate different materials according to their size, shape, or weight. It is employed in a number of sectors, including recycling, manufacturing, food processing, and mining.

3. What benefits can half drum screens offer?

Ans - A half drum type screen has several benefits, including high efficiency, high precision, and low power consumption. Additionally, it has the ability to separate materials of various shapes and sizes.

4. Does utilising a half drum type screen have any disadvantages?

Ans - The expensive price and loud noise levels of a half drum type screen are two potential downsides. Additionally, if the drum is not well maintained, there is a chance of harming the mesh screen.

5. A half drum type screen should be maintained how frequently?

Ans- The type of material being separated and the frequency of use both influence how often maintenance is required. It is advised to frequently check the screen for symptoms of damage and to change the mesh screen as needed.