Multirake Type Screen

Product Details:

- Automatic Grade Full Automatic

- Drive Type Electric

- Material Mild Steel

- Voltage 220-240 Volt (v)

- Click to View more

Multirake Type Screen Price And Quantity

- 1 Piece

Multirake Type Screen Product Specifications

- Electric

- 220-240 Volt (v)

- Mild Steel

- Full Automatic

Multirake Type Screen Trade Information

- Cash in Advance (CID)

- 1000 Piece Per Month

- 7 Days

- All India

Product Description

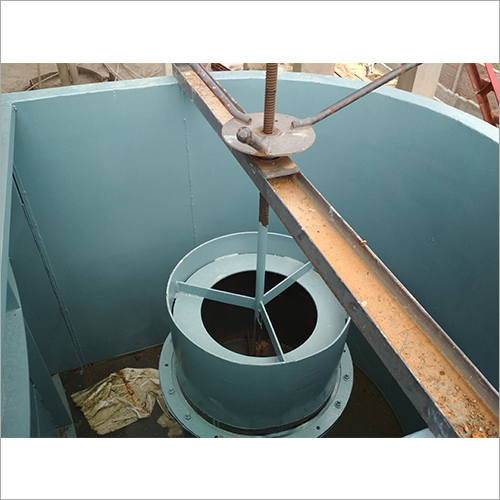

In a comb-like arrangement, several rakes or bars make up a multirake screen. The rakes are pulled through the wastewater flow by a chain or mechanical arm that is attached to them. Rakes go through wastewater, collecting and lifting debris and sediments to provide room for water to flow through.

Usually, the gathered sediments and trash are raised to a higher level before being emptied into a different container or onto a conveyor for further handling and disposal. Some multirake screens could contain a washing mechanism that aids in clearing the rakes of extra organic matter.

Large particles like sticks, plastic, rags, and other waste that could potentially clog downstream machinery or obstruct the treatment processes can be removed effectively thanks to the multirake type screen's design. Depending on the intended removal of particle size and the unique needs of the application, the screen holes or gaps between the rakes can be changed.

Pumps, valves, and downstream operations are often shielded from harm by large objects by multirake type screens, which are typically employed as the first stage of treatment in wastewater treatment plants. They are frequently installed at the beginning of the treatment process or in the plant's first stage of treatment.

Multirake screens provide several benefits, such as the capacity to handle huge flows, the efficiency at eliminating big materials, and the dependability in continuous operation. They can be automated for effective and dependable debris removal, and they only need minimal operator intervention and maintenance.

It's crucial to remember that multirake screens may not be as effective at removing tiny solids or particles because they are primarily made to remove larger trash and solids. For further particles removal, additional treatment procedures like sedimentation or filtering can be necessary.

In order to remove heavy debris and solids from wastewater, wastewater treatment facilities utilise mechanical screening devices called multirake type screens. It uses a comb-like structure with numerous rakes to remove and collect debris from the wastewater flow, protecting downstream machinery and processes in the process.

FAQ

1. What is a multirake type screen?

Ans - A mechanical screening tool used to separate materials of various sizes is a multirake type screen. It is made up of a number of rakes, or overlapping slotted bars, that are linked together by a chain or belt and moved by a motor. Larger particles stay on top as the material is passed through the top of the screen, falling down the slots as it does so and being collected.

2. What advantages do multirake-style screens offer?

Ans - A multirake type screen has a number of advantages. It can be applied in many different ways and is efficient at removing small particles from a variety of materials. Because the parts are simple to change and the screen self-cleans, it also requires relatively little maintenance.

3. What materials can be filtered using a multirake type screen?

Ans - Sand, gravel, coal, wood chips, and compost are just a few of the materials that a multirake type screen is capable of screening.

4. How long does a screen of the multirake type last?

Ans - Depending on the device's quality and usage patterns, a multirake type screen may live up to 10 years or longer.

5. What safety measures must be followed when utilising a multirake type screen?

Ans - When using a multirake style screen, safety precautions should always be considered. Wear safety gear, such as gloves, goggles, and a respirator, and make sure the area is adequately ventilated. In order to lessen the danger of damage, make sure that all moving parts are well lubricated.